As a mining professional, I am constantly seeking ways to enhance safety in the industry. Did you know that mining accidents account for a significant number of workplace fatalities each year? That’s why I am excited to explore how advanced sensor technology can revolutionize safety measures in mining operations.

By providing real-time monitoring of air quality, enhancing structural integrity, and tracking worker safety, these sensors have the potential to detect hazards and risks early, ultimately saving lives. Let’s delve into the future of safety in mining with advancements in sensor technology.

The Importance of Safety in Mining

The safety of workers in the mining industry is paramount. As a mining professional, I understand the importance of training and implementing safety protocols to ensure the well-being of all individuals involved in mining operations.

Training programs equip workers with the necessary knowledge and skills to identify and mitigate potential hazards. This includes teaching them how to properly handle equipment, follow safety procedures, and respond effectively in emergencies. Additionally, implementing safety protocols is crucial in maintaining a safe working environment.

These protocols outline specific guidelines and procedures that workers must adhere to to minimize the risk of accidents and injuries. By prioritizing training and implementing comprehensive safety protocols, we can create a safer mining industry for all workers.

Understanding Advanced Sensor Technology

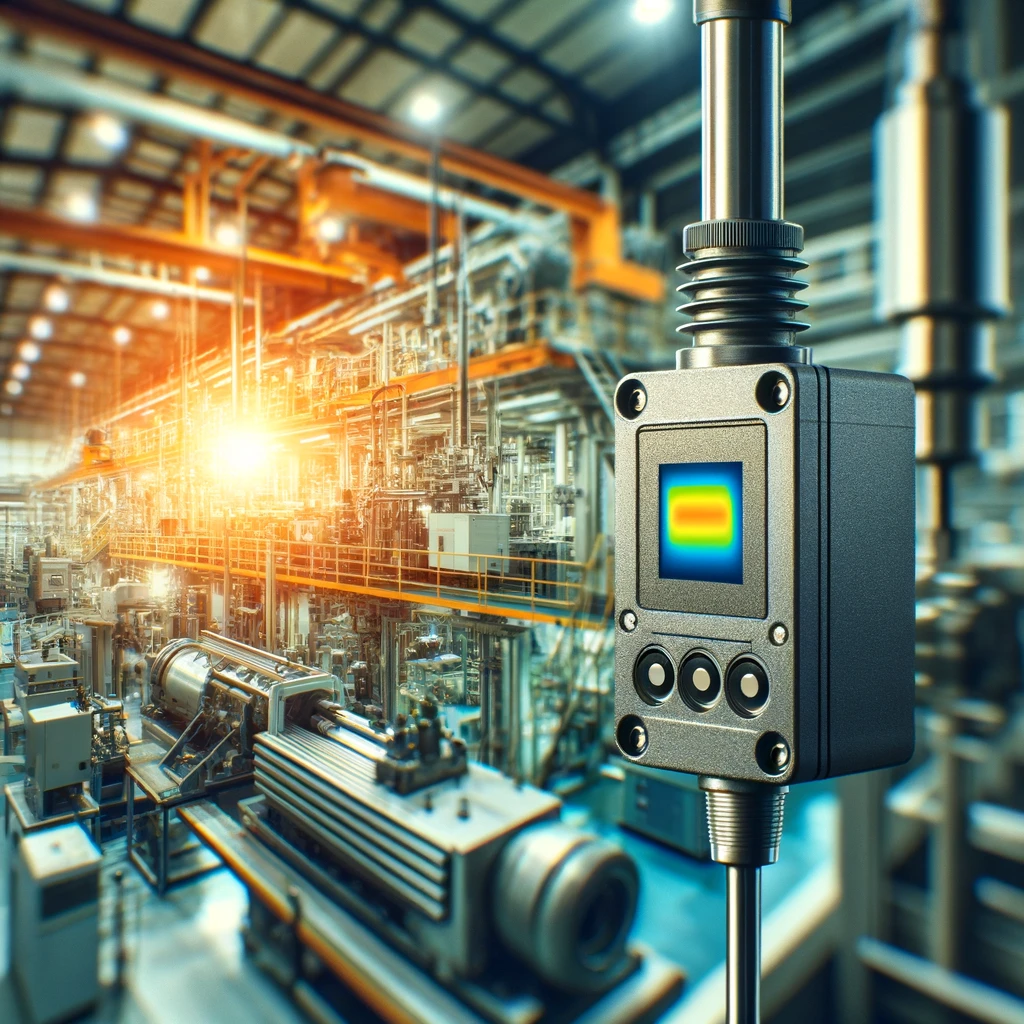

As we continue our exploration of advanced sensor technology in the mining industry, it is crucial to understand its key applications and the benefits it offers. Sensors play a vital role in various aspects of mining operations, providing real-time data on environmental conditions, equipment performance, and worker safety. By harnessing the power of advanced sensor technology, mining companies can proactively identify potential hazards, optimize productivity, and enhance overall safety standards.

Sensor Applications in Mining

I’ve been exploring the diverse applications of advanced sensor technology in the mining industry, particularly in understanding and implementing sensor technology to enhance safety. Sensor technology has already made significant contributions to other industries such as agriculture and healthcare, and its potential in mining is just beginning to be realized. Here are two key points to emphasize:

- Real-time monitoring: Advanced sensors can be used to continuously monitor various parameters in mining operations, such as air quality, temperature, and vibration. This real-time data allows for immediate detection of potential hazards and enables proactive measures to be taken to prevent accidents.

- Personal safety devices: Sensor technology can also be integrated into personal safety devices worn by miners. These devices can monitor vital signs, detect toxic gases, and provide location tracking. In the event of an emergency, these sensors can alert both the miner and the control center, ensuring timely assistance and rescue.

Benefits of Sensor Technology

Continuing from our exploration of sensor applications in mining, let’s now delve into the benefits of advanced sensor technology in enhancing safety. Sensor technology advancements have revolutionized the mining industry by enabling the integration of sensors in mining operations. These advanced sensors offer numerous advantages that contribute to a safer working environment.

Firstly, advanced sensor technology provides real-time monitoring and data analysis, allowing for early detection of potential hazards. By continuously monitoring parameters such as temperature, gas levels, and structural integrity, sensors can alert miners to any abnormal conditions and prompt immediate action. This proactive approach significantly reduces the risk of accidents and improves overall safety.

Furthermore, the integration of sensors in mining operations facilitates automation and remote monitoring. By eliminating the need for human intervention in hazardous environments, sensor technology minimizes the exposure of workers to dangerous conditions, thereby enhancing safety. Remote monitoring enables real-time data collection and analysis, enabling timely decision-making and intervention to prevent accidents or mitigate their impact.

Real-time Monitoring of Air Quality

With the implementation of advanced sensor technology, I can constantly monitor the air quality in real-time within the mining industry. This real-time monitoring of air quality is crucial in ensuring the safety and well-being of workers in the mining sector.

By using smart ventilation systems equipped with sensors, I can accurately measure and analyze various air pollutants such as particulate matter, volatile organic compounds, and gases. This allows me to identify potential health risks and take immediate action to mitigate them. Moreover, real-time air quality monitoring plays a vital role in the environmental impact assessment of mining operations. It helps in identifying the sources of pollution, assessing the effectiveness of control measures, and ensuring compliance with environmental regulations.

Overall, the integration of advanced sensor technology for real-time monitoring of air quality significantly enhances safety and sustainability in the mining industry.

Enhancing Structural Integrity With Sensors

To bolster the structural integrity of mining operations, I rely on sensors to detect any potential weaknesses or vulnerabilities. These sensors play a crucial role in ensuring the safety and efficiency of mining activities.

By continuously monitoring the structural stability of mine shafts, tunnels, and other infrastructure, these sensors help identify any signs of degradation or instability. This early detection allows for timely interventions and preventive measures, minimizing the risk of accidents and equipment failures. Furthermore, sensors can also contribute to improving equipment efficiency and optimizing mining operations.

By monitoring the structural integrity of machinery and equipment, these sensors can help identify potential issues that could lead to downtime or decreased productivity. This proactive approach enables maintenance teams to address problems promptly, maximizing operational uptime and reducing overall costs.

Tracking and Ensuring Worker Safety

Ensuring the safety of workers is paramount in the mining industry, and advanced sensor technology plays a crucial role in tracking and maintaining their well-being. By implementing advanced sensors in the workplace, mining companies can effectively reduce the occurrence of workplace accidents and enhance emergency response.

- Real-time monitoring: Advanced sensor technology allows for real-time monitoring of workers’ vital signs, such as heart rate, body temperature, and oxygen levels. This enables immediate detection of any health abnormalities or signs of distress, allowing for prompt action to be taken.

- Location tracking: Sensors can also be used to track the location of workers within the mine. This is particularly useful in emergencies, as it allows for quick identification and rescue of workers who may be trapped or injured.

Early Detection of Hazards and Risks

By detecting hazards and risks at an early stage, advanced sensor technology enhances safety in the mining industry. Remote monitoring systems equipped with sensors can continuously gather data from various areas of a mine, allowing for real-time analysis and early detection of potential hazards.

These sensors can detect changes in temperature, gas levels, air quality, and other factors that may indicate an increased risk of accidents or health hazards. Additionally, through the use of predictive analytics, the data collected by the sensors can be analyzed to identify patterns and trends that may lead to future hazards.

This proactive approach enables mining companies to take immediate action to mitigate risks, prevent accidents, and ensure the safety of workers. With advanced sensor technology and the power of remote monitoring and predictive analytics, the mining industry can significantly improve safety standards and protect its workforce.

The Future of Safety in Mining: Advancements in Sensor Technology

As we look ahead to the future of safety in mining, advancements in sensor technology will play a pivotal role in further improving hazard detection and risk prevention. The mining industry is inherently dangerous, with various hazards such as rock falls, gas leaks, and equipment failures. However, with advancements in sensor technology, we can enhance safety measures and minimize the risks involved. Here are two key ways in which advancements in sensor technology are improving safety measures in the mining industry:

- Real-time monitoring: Advanced sensors can continuously monitor environmental conditions, such as air quality, temperature, and seismic activity. This real-time monitoring allows for early detection of potential hazards, enabling prompt action to be taken to avoid accidents.

- Wearable sensors: Sensors integrated into personal protective equipment can monitor vital signs and detect dangerous levels of gases or chemicals. This provides workers with immediate alerts, enabling them to evacuate or take necessary precautions to prevent harm.